Engineered for

Precision Manufacturing.

Advanced laboratories and manufacturing capabilities designed to meet the most demanding pharmaceutical-grade standards.

Infrastructure

Advanced Manufacturing Complex

Our Fairfield, New Jersey headquarters houses a comprehensive ingredient technology facility designed to meet the most demanding requirements for pharma-grade production standards.

With over 10,000+ square feet of laboratory and production space, we maintain separate areas for R&D, pilot-scale production, and kilo-scale manufacturing.

Our production facilities are equipped to seamlessly scale from lab to kilo-scale manufacturing with glass and stainless-steel reactors ranging from 50 to 100 liters, alongside large-scale rotary evaporators, advanced filtration units, and dedicated prep-chromatography systems.

Capabilities

Manufacturing Capabilities

Advanced equipment and infrastructure designed for pharmaceutical-grade production from milligrams to kilograms.

Synthetic Laboratories

Fully equipped fume hoods, dedicated bench space, and advanced purification systems for complex syntheses.

Temperature Control

Cryogenic capabilities (-90°C) to high-temperature reactions (200°C+) with precise control.

Production Suites

Segregated production areas with dedicated equipment to prevent cross-contamination.

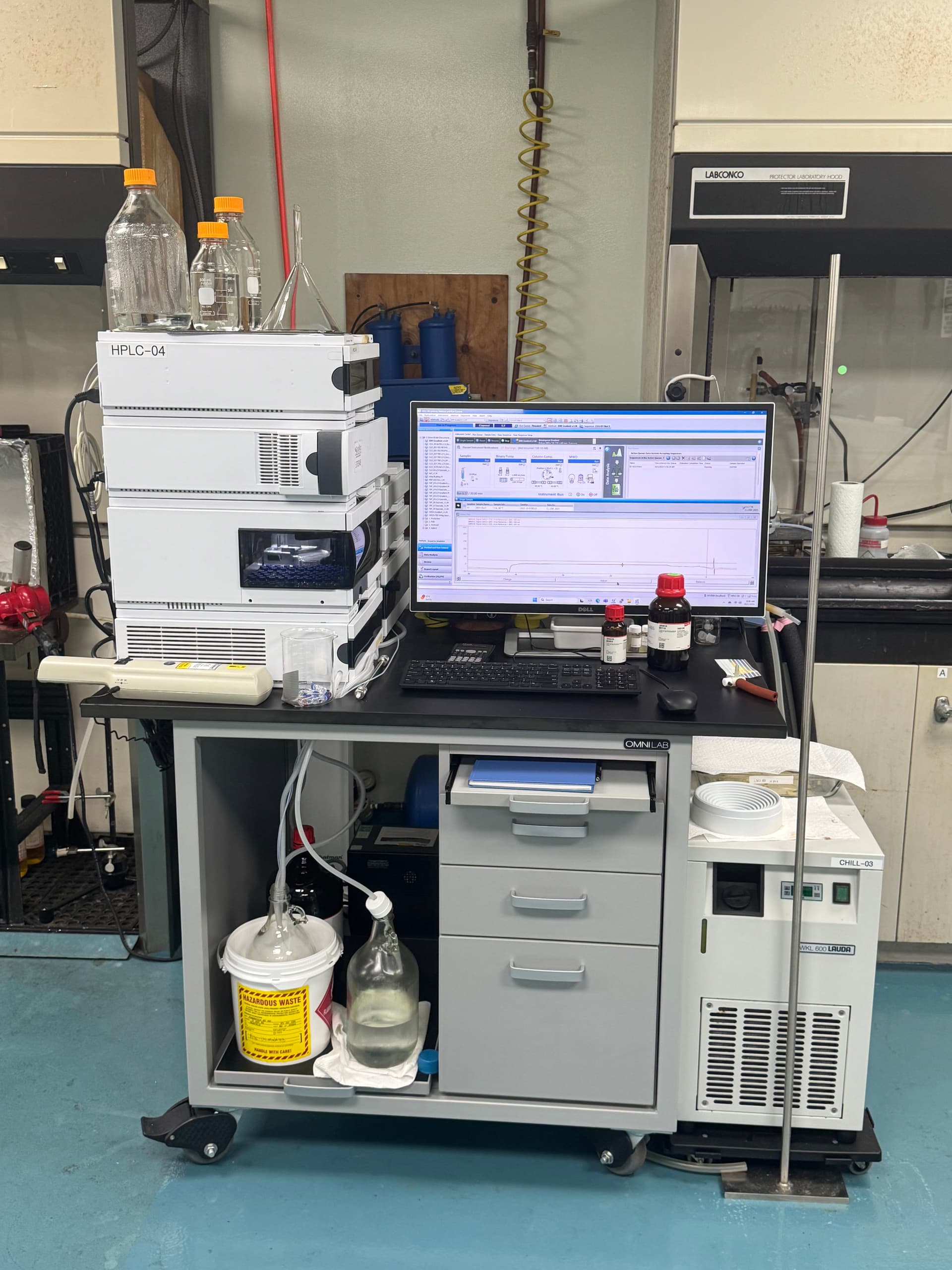

Analytical Laboratory

2 HPLC-MS units, Prep-HPLC, UHPLC, GC-MS, NMR, FTIR, UV-Vis, polarimeter, and titration modules.

Quality Control

Dedicated QC lab with validated methods and equipment for release testing.

Documentation Systems

Electronic batch records, chain of custody, and comprehensive quality documentation.

Instrumentation

Analytical Precision

Comprehensive analytical capabilities for complete characterization and quality control of bioactive compounds.

Chromatography

- 2 HPLC-MS systems with UV/PDA

- UHPLC for rapid development

- Prep-HPLC purification

- Chiral HPLC analysis

- GC-MS analysis

Spectroscopy

- NMR (¹H, ¹³C, 2D)

- High-res mass spectrometry

- FTIR spectroscopy

- UV-Vis spectrophotometry

- Optical rotation

Physical Testing

- Melting point determination

- Karl Fischer moisture

- pH & conductivity

- Organoleptic evaluation

- Precision microbalances

Gallery

Inside Our Facility

Take a look at our advanced laboratories, specialized equipment, and quality-controlled production environments.

Production Laboratory

Manufacturing operations

Precision Analysis

Analytical chemistry

Process Development

Pilot-scale production

Production Reactors

Kilo-scale synthesis

Pressure Reactor

Specialized synthesis

R&D Laboratory

Research & development

HPLC-MS System

Analytical testing

Manufacturing Evaporator

Large-scale purification

R&D Evaporators

Process development

Compliance

Quality Assurance

Rigorous quality systems ensuring consistency, safety, and regulatory compliance for every production run.

Rigorous Protocols

Comprehensive analytical testing, validated processes, and batch documentation for every run.

Pharma-Grade Standards

Manufacturing practices following the spirit of GMP with controlled environments and validated equipment.

Safety & EHS

Comprehensive program including chemical hygiene, waste management, and emergency response.